CleanTec Industry News

The Importance of Dilution Equipment for Chemicals

Expired

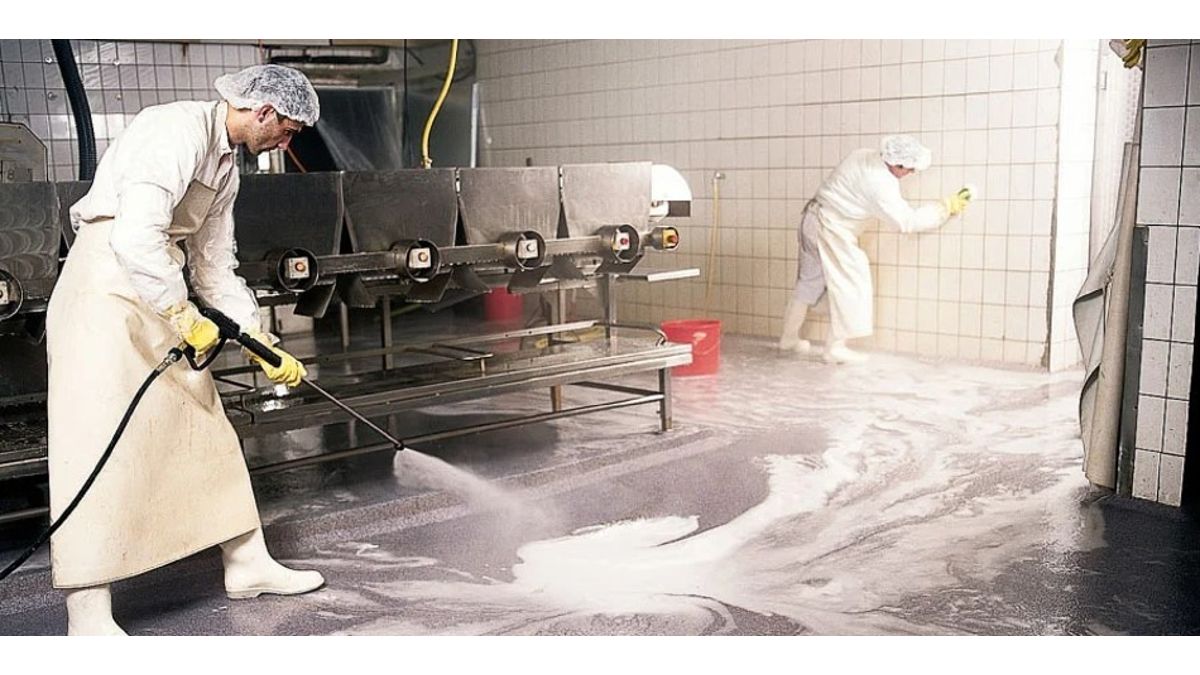

Latin America. Elements that optimize human tasks are appearing on the market every time. Specifically in the cleaning and disinfection (LYD) sector, there are devices that facilitate and optimize the work carried out at an industrial and institutional level: dilutors. Flow Chem, a specialist in the field, explains in more depth the characteristics and benefits of this type of solution.

What is a chemical dilutor or dilutor equipment?

It is a device for dosing chemical products, transforming a pure product into a product diluted to the desired concentration, avoiding waste and ensuring the correct dosage of disinfectants, detergents, degreasers, among others.

What is the importance of dilution equipment for chemicals?

It is advisable to use chemical dosing equipment in industry due to the added values that they bring to the production process.

Zero waste of chemical product: since in the manual realization of the dosages there may be spills or drips of product generating an additional expense.

Process cost-effectiveness: Due to how quickly chemicals are mixed with water, this reduces labor time.

Correct dosage: it is important to use the dilutions of chemical product delivered by the supplier so as not to affect its performance, that is where the diluting equipment becomes important, since they are calibrated with the exact dosages that we require in a certain process.

Safety for employees: diluting equipment provides us with safety and ease in the dilution operation since the employee does not have direct contact with the pure product, avoiding product spills, splashes and overexertion when having to turn heavy cans.

Aesthetics: due to their design, the diluting equipment brings order and aesthetics to the stations where they are installed, in addition several products can be conditioned in series

Types of Dispensing and Dilution Equipment in Industry

There is mechanical, electrical and electronic equipment for the dosing and dispensing of chemical products

Manual Operated Hand Soap Dispensers

Hand Soap Dispensers with Sensor

Chemical dilutors for one or more products

Pure product dispensers

Manual water pressure operated skimmers

Compressed Air Operated Manual Frothers

Compressed Air Operated Foaming Carts

Handheld, electric, and compressed air-operated nebulizers

Dosing pumps for laundry

Dosing pumps for earthenware and basket washing systems

Dosing pumps for biodigesters (grease traps and septic tanks)

Chemical dosing equipment for water treatment

Installation

The installation of the dosing equipment is simple and easy to operate by the operating personnel and its cost is freed over time due to its multiple added values that contribute to the process directly in savings and profitability. Likewise, chemicals should be used at the specific concentrations recommended by the supplier, as their efficiency and effectiveness depend directly on it.

More information in www.flowchem.com.co